DJJ Precision Engineering -

High-precision Turned Parts

Subcontract Manufacturing

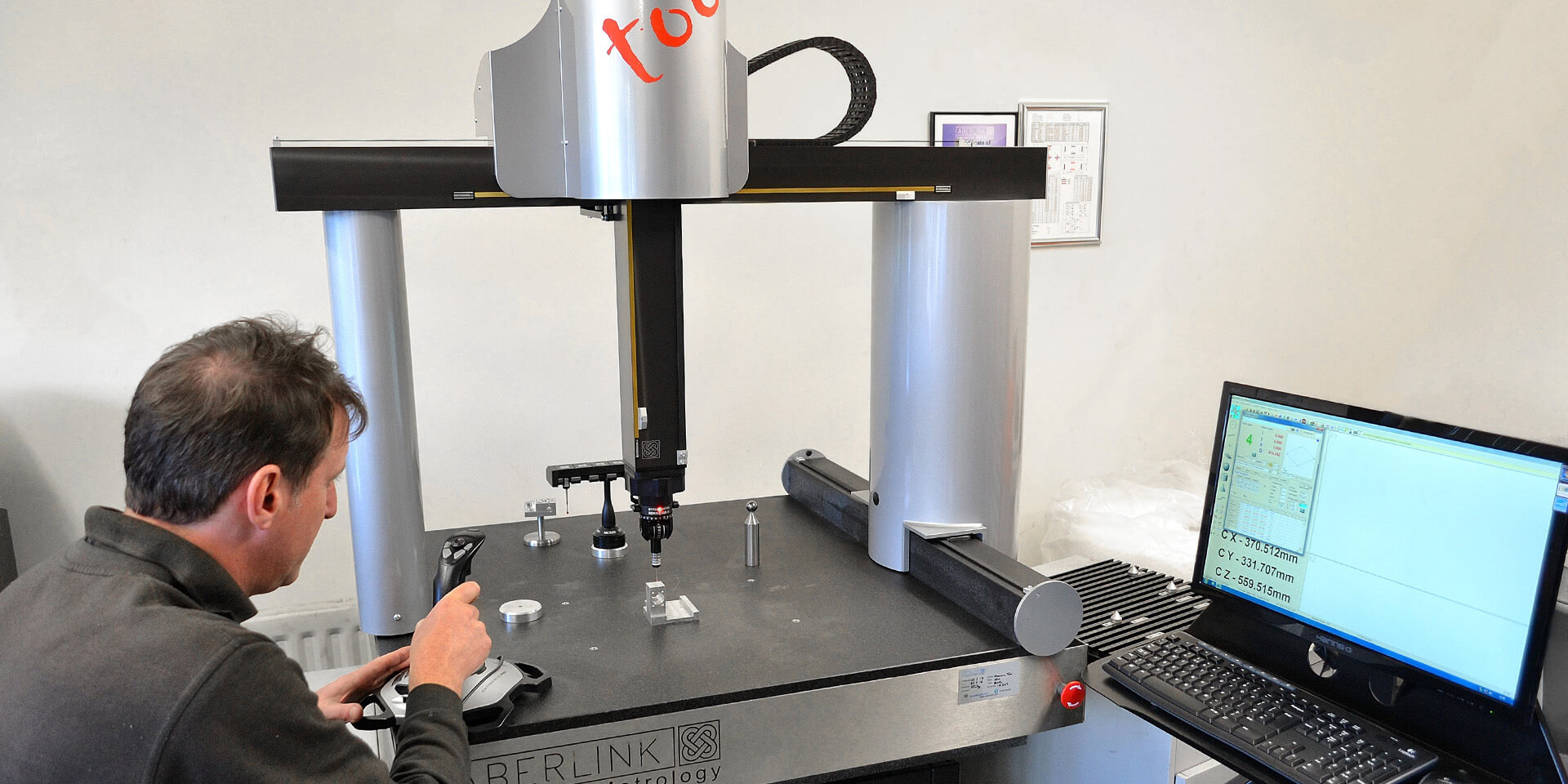

Axiom too CNC CMM Case Study

Since the company's formation in 1976, South Wales based DJJ Precision Engineering Ltd. has earned an enviable reputation for the quality of its output. Prompted by customer demand, over the past four decades the company has continually increased the range of services it provides and has significantly expanded its productive capacity.

DJJ now manufacture and supply an impressive range of high-precision turned and milled parts to many well-known UK based and international companies. Amongst other demanding sectors currently served, are the global automotive, aerospace, marine, defence, medical and gas industries.

A policy of regular staff training, continuous investment in the best available machine tools, the procurement of advanced inspection aids and the administration of a stringent quality regime has supported the company's impressive growth.

Dennis Jones Managing Director of DJJ explained "We continue to invest heavily in high end CNC machinery and have invested in excess of £1million over the last 3 years. This has abled us to offer our clients a complete 'one stop shop' service that operates around the clock, we are capable of providing everything from design and prototyping expertise through to full batch production and global delivery.

"Our quality ethos permeates every aspect of our activities. Throughout every process, all parts engineered by DJJ are subject to thorough inspection routines, including first-off, intermediate and final inspection procedures to ensure zero defect deliveries.

"We supply our clients with Part Submission Warrants, Appearance Approval reports, Dimensional Reports and Material Test reports, and follow their instructions and design specification.

"The implementation and adherence to ISO 9001 helps enable continuous improvement to our quality management systems (QMS) and processes. In turn, this improves the ability of our operations to meet customer requirements and expectations."

To help the company retain its reputation for quality, raise its precision capabilities and to enable the automatic generation of inspection reports, Dennis Jones, recently searched for a suitable advanced Coordinate Measuring Machine (CMM). In order to handle the large volume of accurate work passing through the company's busy quality department, the proposed precise CMM needed to be able to perform rapid, automated measuring routines and be easy to program and operate.

Dennis Jones continued. "Having identified the need for an advanced new CMM that could remove the potential for bottlenecks from our Inspection Department, we investigated the various options. Although we considered several alternatives, a practical demonstration of Aberlink's impressive Axiom too convinced me that the machine had all of the features we needed. In addition to having the required accuracy specification, the Axiom too was also able to perform the quickest, automated CNC measuring routines of all of the CMMs we looked at. Also, the Axiom too's large component support meant that we could load multiple components and measure them in a fully automatic CNC mode. Other factors, such as Aberlink's easy-to-use 3D measurement software and the CMM's cost effective price, helped convince us to place an order.

"To enable even quicker inspection routines we specified the machine fitted with a Renishaw RTP20 probe system. Also, to allow the fast, accurate measurement of low-profile 2D parts, and small and delicate components, we ordered Aberlink's high resolution CMM camera system that enables non-contact inspection techniques to be undertaken."

The Axiom too is the best-selling CMM from Aberlink Innovative Metrology, the largest UK owned Coordinate Measuring Machine manufacturer. Available in manual and CNC variants and in a range of capacities, the recently upgraded CMM can truly be described as the complete Inspection Centre; high measuring accuracies are achieved through the use of the latest metrology techniques and advanced in-house manufacturing methods. The Axiom too boasts an aluminium bridge with a very low thermal mass, rendering the machine ideal for use either in controlled environments or within less than perfect shop-floor conditions. Thanks to the Axiom too's use of advanced materials, the machine's reduced inertia results in class leading speed of operation. For increased accuracy air bearings of optimised stiffness are employed on all axes, whilst a granite Y Beam allows preloading of bridge bearings in both directions. Borrowed from the Aerospace industry, the CMM's sturdy component support consists of an advanced granite/aluminium honeycomb construction, this technology, provides natural damping and further improves the machine's thermal properties. Despite the Axiom too's generous measuring volume 640x600x500 or 640x900x500, the machine's compact design occupies a relatively small footprint, with the controller and all peripherals housed within the Axiom too's workbench.

The easy to use Axiom too utilises Aberlink's famous, intuitive 3D software, ensuring greater user productivity and profitability. A welcome bi-product of any Aberlink CMM inspection routine is that a simultaneous picture of the measured component is created on the computer screen. Dimensions between the measured features, mirroring those that appear on the component drawing, are then picked off as required. In essence this 'smart' software represents an intelligent measuring system that is able to automatically recognise and define the various features being measured. Aberlink 3D is claimed to be the easiest to use CMM software currently available, as a result a complete novice is usually able to perform relatively involved measurement routines after just 5 minutes training.

Dennis Jones concluded. "Since the Aberlink Axiom too's installation our operators have quickly mastered our new CMM and it has quickly become an invaluable tool for confirming the quality of our output. The high precision nature of the Axiom too enables us to undertake the most accurate and complex of measuring routines, whilst its speed has eliminated the possibility of inspection hold-ups. In addition, our new Aberlink CMM's ability to generate in-depth inspection reports has been welcomed by our customers."

"Illustrating the Aberlink CMM's value to us and the importance we place on the quality of our output, the 'Inspection' page of our company website features a video clip of the Aberlink CMM in action."